Is your smart farming control system built industrial grade?

Today’s Market:

In today’s market, fully automating a commercial horticulture facility with smart farm control systems can range in price from just a few thousand to a few million dollars. If you’re a farmer with a very small area, hobby systems are a great fit, but if you operate a commercial cultivation facility, you need an industrial grade solution. Admittedly, purchasing an industrial grade control system requires a sizable investment. Outside of the smart farming industry, these systems are rarely so expensive. The truth is, most of the early smart farming companies have evolved into very large brands with massive corporate overhead. Many are still overcharging, because they can. As more industrial smart farming companies emerge, like Mandala Automation, we can expect to see the price gap between hobby and industrial systems diminish significantly.

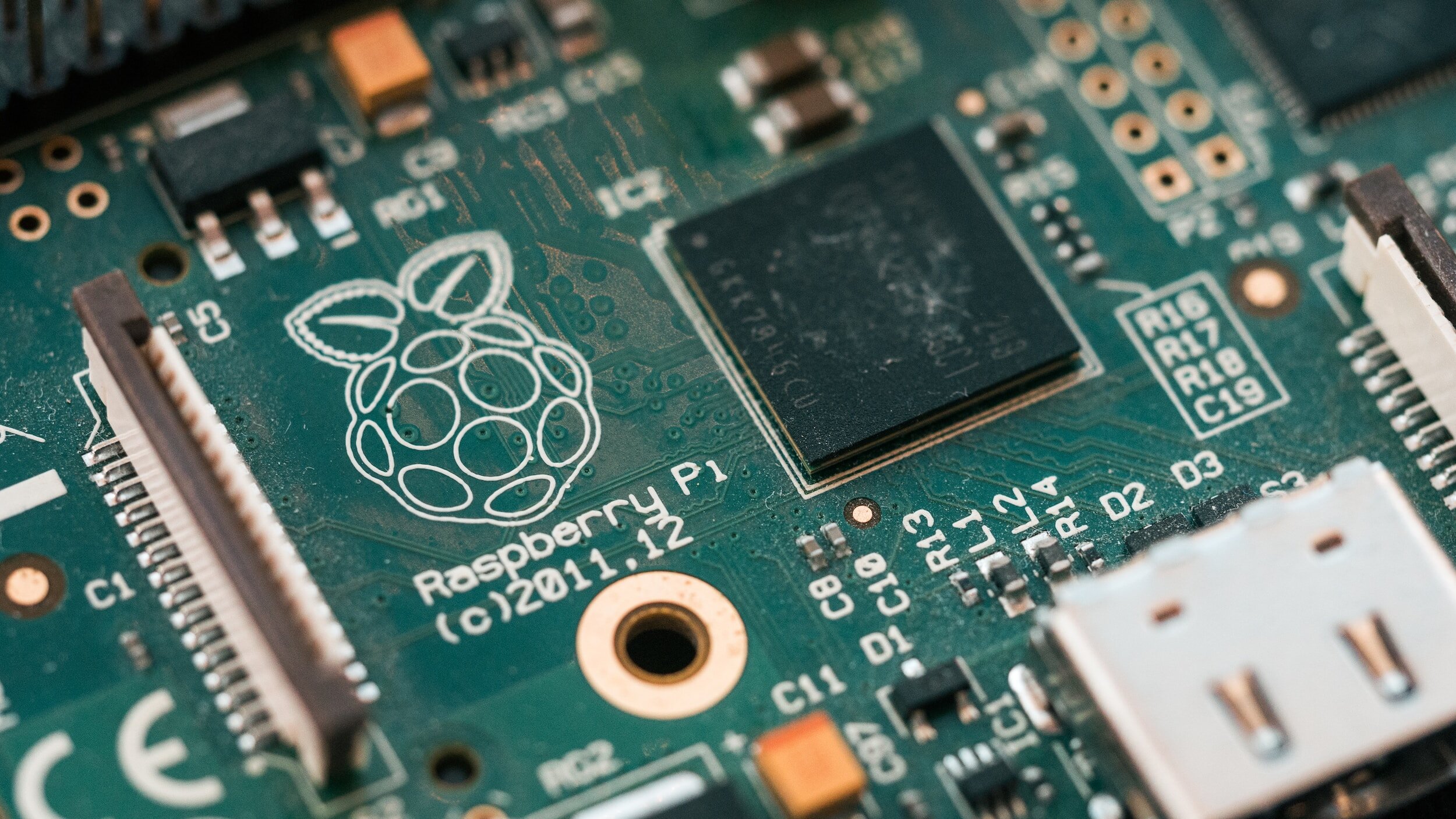

Hobby systems use non industrial, ultra cheap hardware components made in China. The technology was intended for college projects, or other small hobby applications around the home. Some hobby systems are now coupled together with an appealing interface supported by cheap, unreliable hardware components. To make things more confusing, some of the hobby companies are now masquerading as industrial grade. Hobby companies may not be overcharging, but they are under building in a race to see who can build it the cheapest. These choices in the market leave commercial cultivators with limited options that are both reliable and affordable.

Quality Matters- Cheap, unreliable components can lead to interruptions in production, delays, and losses.

The advantage of building industrial grade:

A conformal coating is applied to a circuit board.

What is the advantage of building industrial grade and what defines industrial grade components? Industrial grade systems are built using hardened electronic circuit boards which are engineered for maximum durability and reliability. These standards were adopted many years ago to support the automotive industry and later carried over into oil & gas, chemical, aviation, and other industries who depend on control systems to protect human life, environment, and mission critical facility equipment. Industrial hardware is engineered to run continuously for 20 years or more without malfunction, even when subjected to hazardous and unfavorable environments. Additionally, industrial systems are built to support unlimited scale and provide third party integrations with other facility packaged systems and sensor sets.

Manufacturers of industrial grade hardware invest decades proving their components meet the reliability standards set by the seasoned industrial markets. The components require industrial certifications and must undergo years of testing and validation before it’s ever considered for use in an industrial application. For industrial facilities, reliability is paramount with millions of dollars at stake if a control system hardware failure occurs. Choosing an industrial grade platform ensures you will be able to obtain parts down the road in the rare case you have a component failure or want to expand your facility.

Mandala Automation uses only widely accepted industrial hardware and manufacturers that have already proven their reliability to the seasoned industrial markets since the 1970s. Building industrial grade also means you get to enjoy the benefit of a 20+ year return on investment.

Here are a few red flags indicating non industrial grade:

The cables are RJ11, used in the 1970s & 1980s for phone communications

The company says they build their own controls hardware

Your system controller lives on the internet and is not a hardware device at your site

The control wires are connected to a board which is controlled over the internet

The hardware components look and feel like cheap plastic

Your system requires you to mount dozens of individual components on a wall

Your system is not properly fused

Your system is using an arduino or a Raspberry Pi controller

The company is unable to lead you to the industrial components website for validation

Your stuck with proprietary equipment and are forced to use their sensors

It says made in China